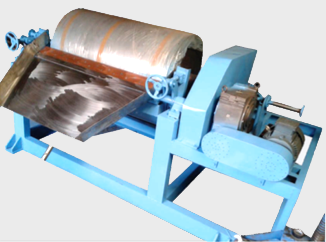

Drum Drier / Flaker

Drum Drier / flaker are used to make flakes continuously from molten material. The molten material to be flaked is poured on the tray of Flaker which get solidified on the surface of rotating drum which is scraped to get flakes of desired thickness. We manufacture Drum Flakers of various capacities depending on the production of flakes required.

Construction

Drum Flaker consist of Drum fabricated from Mild Steel or Stainless steel

with hollow shafts on both ends. The drum surfaced is duly ground and hardcromed with

superior finish to get uniform thickness of the flakes. The drum is provided with a Hollow

Shaft for entry of water for sprinkling on the inside of the drum for cooling purpose. The

drum is mounted on self aligning spherical roller bearing for smooth rotation and to take

care of scraping loads. A jacketed feed tray is provided below the drum in which molten

material is poured, the molten material gets coated to the drum by a sizer pipe.

The Scraping arrangement is made of Copper or Fiber Blades to scrape the flakes. A discharge

tray is provided to collect the Flakes.

Bearing

The drum is provided with self aligning spherical roller bearings for smooth rotation & take care of scrapping loads.

Gear Drive

The drum is rotated by chain sprockets arrangement with the reduction box to absorb the vibratory load of the scrapper. The Gear Box is driven by variable frequency drive.