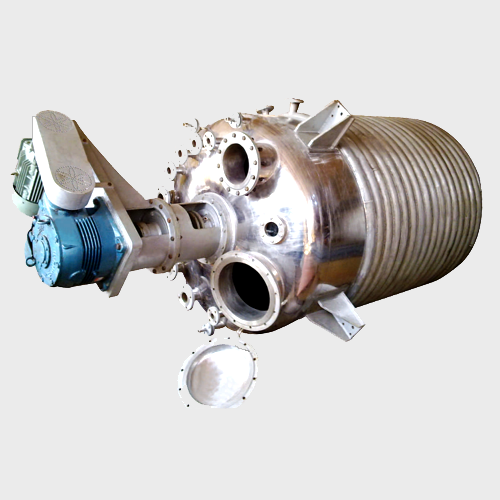

Limpet Coil Reaction Vessel

Reaction Vessel is one of the most important equipment of any chemical, food, drug ,dye & allied industries. There are different types of Reaction Vessels broadly classified as Jacketed, Limpet Coil in Body Flange & Welded type & Top Open type with or without Internal Cooling or Heating Coil as per the need of the Process. We manufacture Reaction Vessel with capacity ranging from 100 liters to 20,000 liters in material of construction stainless steel & mild steel & rubber lined depending on the requirement of the material to be processed.

Construction

The construcon of Limpet Coil Reactor is same as that of Jacketed Reactor

except instead of Jacket on the Shell of Reactor Limpet Coil is welded on it. Limpet Coil

Reaction Vessel consist of a Cylindrical vertical shell with standard torospherical dish on

both ends.

Limpet Coil is Half round Pipes welded on the outer surface of the shell and also on the

bottom dish of the Reactor. Limpet coil is made of either Mild Steel Or Stainless Steel. It

is either Double end double start for both heating and cooling through limpet coil or Normal

Single coil for either heating or cooling. Limpet Coil Welding is performed by using high

grade filler rods depending on MOC of the Limpet Coil to withstand design pressure.

Drive

The drive is designed to give maintenance and trouble free performance. The Agitator Shaft is coupled to the Reduction Gear Box with Flexible coupling.The Reduction Gear Box is mounted on the Top of the Lantern Assembly and is driven by Motor using V belt pulley. Variator or AC drive can by used to get variable speed of the Agitator if desired.

Mounting

Four lugs support are provided on the Shell of the reactor to mount it on the Platform of the Factory. Platform can also be prefabricated and assembled at site.

Welding

Welding work is performed by Argon Arc process using Good Characteristic Filler rods on all S. S. Parts. M.S. Parts welding is performed by D. C Arc welding process using suitable electrodes of Advani Oerlikon make.

Finish

All weld joints will be finished from inside and outside, S S. Parts is cleaned from inside and outside. Two coates of primer / red oxide will be given on M.S. parts from outside

Testing

Equipments are tested Hydraulically as per design Pressure.